Perforation on dynamic depression technology ΔP (DeltaP)

DownloadOperating principle

After the action of the shaped charges is over, the process of abrupt filling (collapse) of the implosion chambers and the internal cavities of the perforation gun with the well fluid begins - a high-speed impulse of dynamic depression is formed, a compacted rock crust with reduced permeability is detached from the surface of the channels.

Advantages

If a perforation system on dynamic depression is used, the rock permeability in the high-density zone compared to the undisturbed formation zone can be close to 1.0, in contrast to 0.05-0.3 typical for perforation on static depression.

Perforation technology on dynamic depression DP (DeltaP) can be used for:

- perforations on wireline;

- perforations on tubing;

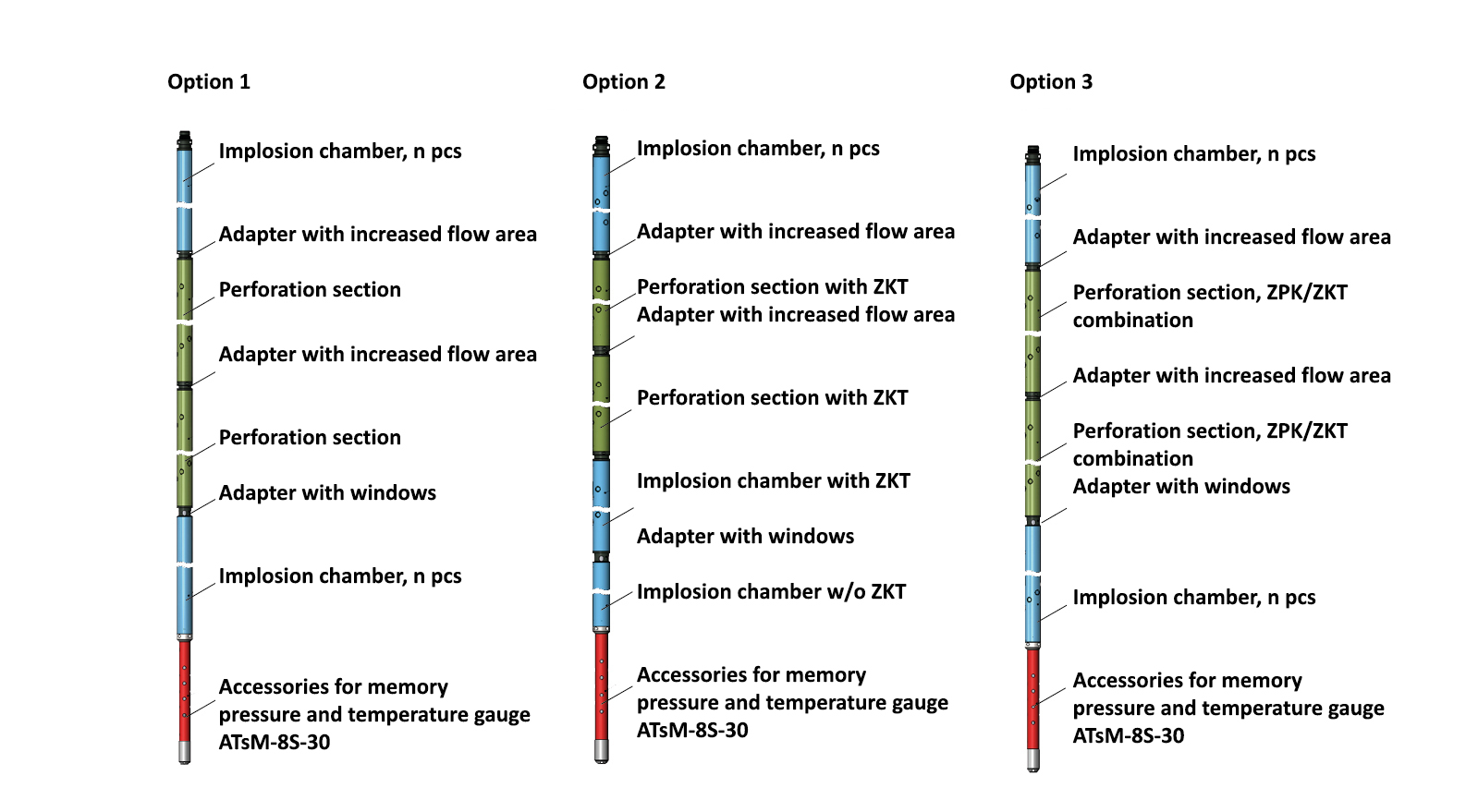

- perforation of several intervals with different (different from each other) permeability.

Perforation on static depression is a method for removing damage (high-density zone) of the perforation channel when perforating with jet guns. The perforation on dynamic depression technology DP cleans perforation channels more efficiently than conventional methods of perforation on static depression, making clean perforation channels in wells and achieving better productive capacity or injection rate.

JSC “BVT” works on the development and implementation of the latest BPO technologies. The perforation on depression is an effective method for cleaning the high-density zone in the perforation channel during the secondary drilling of reservoirs.

Traditional perforation techniques do not always provide satisfactory results in terms of productivity and safety. This technology guarantees an optimal level of depression during BPO. This goal is achieved due to the use of specialized equipment and is simulated by a mathematical method.

DeltaP technology guarantees more effective cleaning of perforation channels in comparison with the conventional methods. Clean channels in wells enhance productivity and increase oil recovery.

The process of “DeltaP” perforation includes the following successive stages:

- Detonation. Formation of a channel in a reservoir causing an increase in pressure.

- Dynamic depression. Filling perforator cavities.

- Cleaning of perforation channels. Reduction of pressure in the cavities.

The DeltaP technology optimizes the processes of dynamic depression during perforation - the optimal pressure is achieved after the channel cavity is formed in the layer. As a result, the productivity of the well increases, the volume of damaged zones reduces, the channels are cleaned during perforation, when more than one run is required.